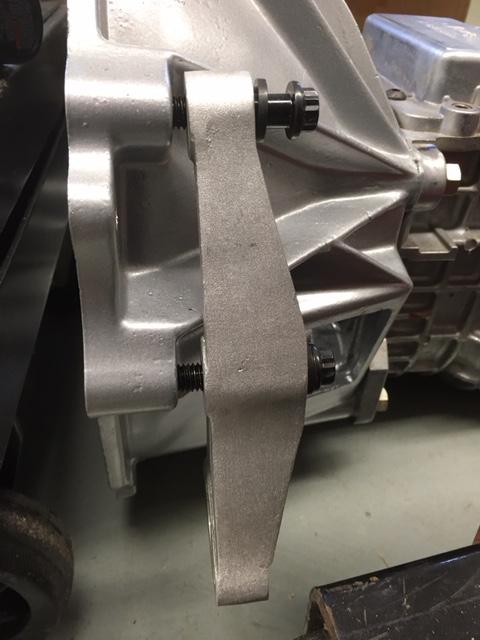

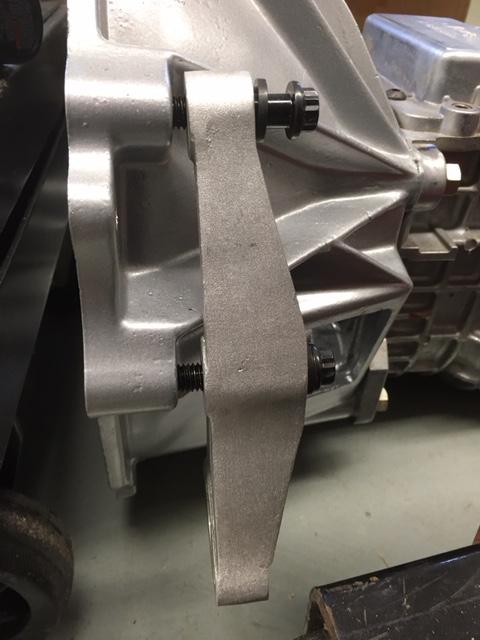

Many thanks. The CAT aluminum bracket is in no way flimsy. I prefer it because it mounts away from the headers, and is aluminum rather than steel. The aluminum should absorb less heat, and dissipate heat better. You can see from my photos above that the steel one is close to the headers, both on the mounting plate and on the leg/3rd mount. I can clearance it, but it will still be close to the header tubes by design. Lastly, the diaphragm pressure plate from modern driveline will not require the pressure of the heavy-duty finger-style pressure plate that I used in the 80's - that one was seriously heavy (LOL, the old alignment shop owner told me 'takes two men and a boy to depress that clutch').

If the aluminum one flexes or fails, I'll own it and post here to save someone else the same headache. I really can't see that happening, because if that aluminum mount won't work for my application, then it probably won't work for anyone.

Headers should be back from Jet Hot in a week or two, I'll follow up with pictures when it is all assembled.

--Woody