- Messages

- 300

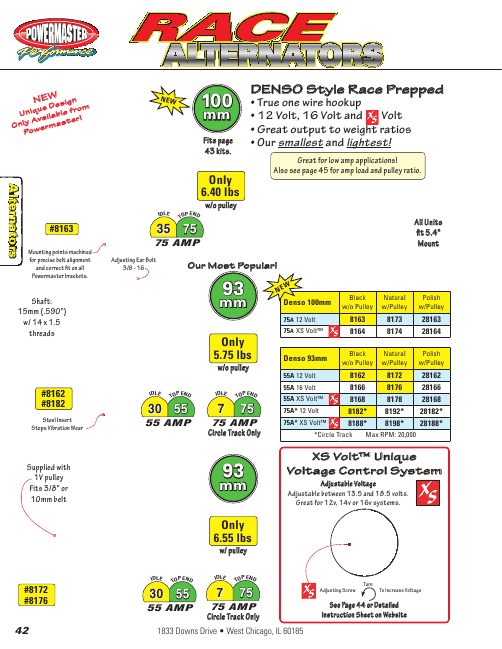

I have the smaller size and saw those a few months back. Figured I would get what I have going first and upgrade if needed. Things are getting costly these days.Powermaster now has a 100mm with same deminsions as 93. This is a polished one I got and will install it with Hoghead's Bracket. It puts out 75A. Also had the Bracket Powdercoated black.

Also for everyone doing alternator upgrades make sure your main wire from the alternator and related connections (amp meter if used) are capable. I recall the stock stuff from the generator was not of a large enough gauge for much over the stock generator/alternators that were stock. I don't have stock wiring so not going to be a problem, but for those that do good idea to checks gauge and amperage ratings. Likely 8 gauge for 55 amp and 6 gauge for 75 amp being somewhat overkill but safe for shorter runs 5-10 feet. Again not sure what's in the stock harness.